What Are Hydraulic Seals?

Hydraulic seals are components designed to prevent fluid leakage from hydraulic cylinders at high pressures and temperatures. They maintain the integrity of hydraulic systems by containing the fluid within the system while also preventing contaminants from entering. Without effective seals, hydraulic systems would be prone to leaks, leading to decreased efficiency, increased maintenance costs, and potential safety hazards.

Types of Hydraulic Seals

Hydraulic seals come in various types, each tailored to specific applications and operating conditions:

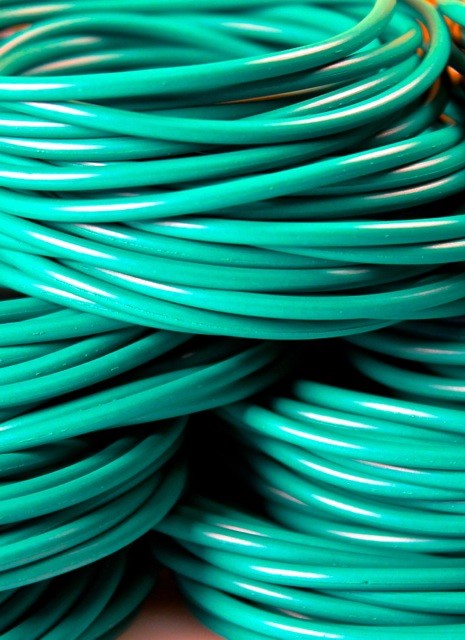

- O-Rings: Perhaps the most common type of hydraulic seal, O-rings are simple, circular seals used in static and dynamic applications. They’re versatile, cost-effective, and can withstand a wide range of pressures and temperatures.

- U-Cups: U-cups, also known as lip seals or rod seals, feature a U-shaped profile and are typically used in hydraulic cylinders. They provide excellent sealing performance and can accommodate moderate misalignment.

- Wiper Seals: Wiper seals, as the name suggests, are designed to wipe contaminants from the surface of the piston rod, preventing them from entering the hydraulic system. They play a crucial role in extending the life of hydraulic cylinders.

- Vee Packing: Vee packing consists of multiple stacked rings, typically made of rubber or plastic, arranged in a V-shape. This design provides exceptional sealing performance, making it suitable for high-pressure applications.

- Rotary Seals: Rotary seals, also known as shaft seals or oil seals, are used to seal rotating shafts in hydraulic systems. They prevent fluid leakage and keep contaminants out while allowing the shaft to rotate smoothly.

How Do Hydraulic Seals Work?

Hydraulic seals work by creating a barrier between moving components in a hydraulic system. When properly installed, they form a tight seal against the housing or cylinder wall, preventing fluid from escaping. The effectiveness of a hydraulic seal depends on factors such as material selection, design, and installation quality.

Importance of Proper Seal Maintenance

Maintaining hydraulic seals is crucial for ensuring the long-term performance and reliability of hydraulic systems. Regular inspection and replacement of worn or damaged seals can prevent costly downtime and repairs. Additionally, using the correct type of seal for the application and operating conditions is essential for optimal performance.

Please reach out to Caliber Sealing Solutions, Inc. for all your hydraulic sealing needs!