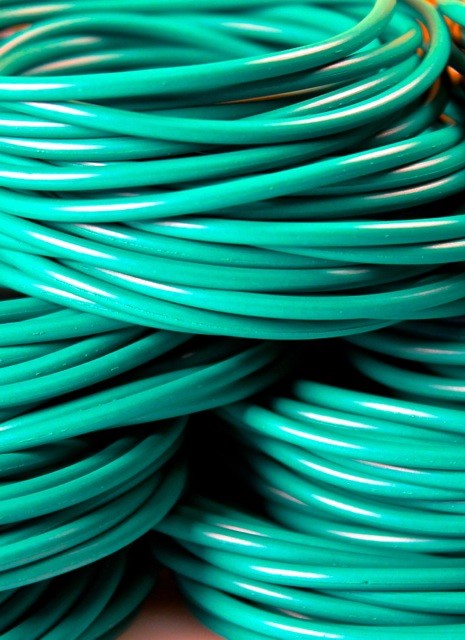

Unlocking the Power of PTFE: The Benefits of Utilizing Polytetrafluoroethylene (PTFE) for Seals

In the realm of industrial engineering and manufacturing, the choice of materials can significantly impact the performance, longevity, and reliability of products. When it comes to sealing solutions, one material stands out for its exceptional properties and versatility: Polytetrafluoroethylene, commonly known as PTFE.

Let’s dive into the many benefits that PTFE offers for seals in various applications.

Chemical Resistance

PTFE boasts unparalleled resistance to a wide range of chemicals, acids, and solvents. Its unique molecular structure, characterized by strong carbon-fluorine bonds, renders it inert to most corrosive substances. Consequently, PTFE seals maintain their integrity even when exposed to aggressive environments, ensuring leak-free performance and safeguarding equipment from chemical damage.

Temperature Stability

One of the hallmark traits of PTFE is its exceptional thermal stability. It can withstand extreme temperatures ranging from -200°C to 260°C (-328°F to 500°F) without losing its mechanical properties. This remarkable heat resistance makes PTFE seals suitable for applications subjected to fluctuating temperatures, such as aerospace, automotive, and chemical processing industries, where reliability under extreme conditions is paramount.

Low Friction Coefficient

PTFE exhibits an ultra-low coefficient of friction, surpassing that of most other materials. This property imparts excellent lubricity to PTFE seals, reducing wear and tear and minimizing energy consumption in dynamic applications. Whether in pneumatic systems, hydraulic machinery, or rotating equipment, PTFE seals facilitate smooth operation, prolonging the lifespan of components and enhancing overall efficiency.

Non-Stick Surface

The non-stick nature of PTFE prevents adhesion and buildup of contaminants, such as oils, greases, and particulate matter. This inherent self-cleaning property ensures that PTFE seals remain free from debris accumulation, thereby mitigating the risk of seal failure and maintaining optimal performance over prolonged periods. Additionally, the easy release characteristic simplifies maintenance procedures, contributing to cost savings and operational efficiency.

Dimensional Stability

Unlike some elastomeric seals that may undergo deformation or creep over time, PTFE maintains exceptional dimensional stability under mechanical stress. Its inherent rigidity and resistance to compression ensure consistent sealing performance, even in high-pressure applications. This dimensional integrity translates to enhanced reliability, reduced downtime, and increased operational efficiency across diverse industrial sectors.